Orifice plate flow meters and turbine flow meters are two of the most widely used flow-measurement devices in industrial systems. Each type operates with a distinct principle. Each offers specific strengths. Each reveals certain limitations. Engineers choose between them based on accuracy requirements, fluid properties, installation constraints, and operating conditions. Understanding how these meters compare helps ensure better system performance and more reliable measurement. This article examines the major differences, explains how each meter works, and explores how their characteristics affect real-world applications.

Understanding the Measurement Principles

How Orifice Plate Flow Meters Work

Orifice plate flow meters use a simple principle. They rely on differential pressure. A thin plate with a precisely machined hole is placed inside a pipeline. Fluid flows through the hole. Pressure drops as fluid accelerates through the restriction. The difference between upstream pressure and downstream pressure allows the system to calculate flow rate.

This method depends on predictable fluid behavior. It works well for many gases and liquids. The design is simple. The plate is easy to manufacture. The measurement concept has been in use for many decades. Due to its reliability, it appears in many industrial standards.

How Turbine Flow Meters Work

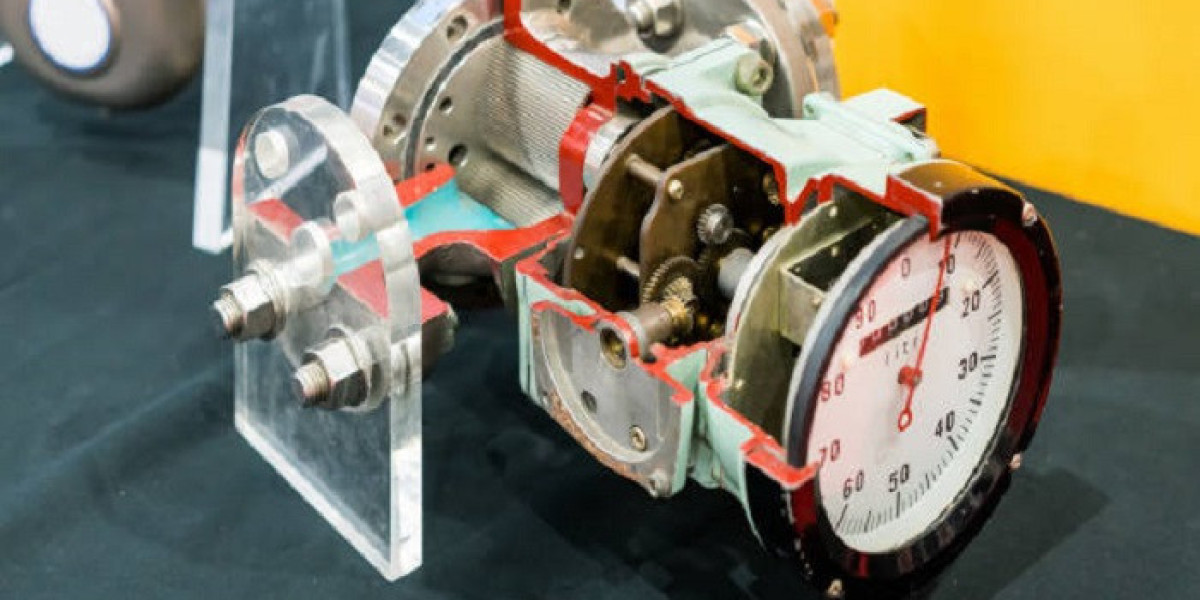

Turbine flow meters rely on mechanical rotation. Fluid enters the meter body. It strikes a multi-bladed turbine rotor. The rotor spins in proportion to flow velocity. A magnetic or optical sensor tracks rotor speed. The system translates rotational speed into volumetric flow rate.

This method directly reflects actual movement of the fluid. It can be accurate when fluid properties remain stable. It is suitable for clean, low-viscosity liquids. It is also used for some gases when conditions are controlled.

Differences in Accuracy and Performance

Accuracy Under Ideal Conditions

Turbine meters are typically more accurate than orifice plate flow meters. Their precision can be high because rotor rotation directly reflects fluid flow. When the fluid is clean, stable, and consistent, turbine meters provide tight measurement tolerance.

Orifice plate flow meters offer lower accuracy by comparison. Their readings depend on predictable pressure drop. They assume ideal flow profiles. Disturbances upstream or downstream affect results. For many industrial processes, the accuracy is acceptable. For high-precision operations, limitations may appear.

Impact of Fluid Properties

Orifice plate flow meters handle a wide variety of fluids. They work with liquids and gases. They tolerate mixtures and varying viscosities. They do not require perfectly clean fluids.

Turbine meters, however, rely on moving parts. Contaminants can damage the rotor. High viscosity can slow rotation. Variability in gas density can distort readings. These meters perform best with clean, low-viscosity fluids.

Installation Considerations

Space Requirements and Flow Profile Needs

Orifice plate flow meters require long straight pipe sections. The flow profile must be smooth. Distorted flow can cause inaccurate pressure readings. Engineers must follow standards for piping length.

Turbine flow meters also need straight pipe runs but often require less length than differential pressure devices. Even so, turbulence or swirl can still influence rotor behavior. Alignment and orientation must be precise.

Ease of Installation and Maintenance

Orifice plate flow meters are simple. They have no moving parts. The plate can be replaced easily. Maintenance typically focuses on verifying plate condition and monitoring pressure taps.

Turbine meters require maintenance of mechanical components. Bearings wear over time. Rotors may require cleaning. Sensors need calibration. While turbine meters can last long when cared for, maintenance demands are greater.

Durability and Reliability

Mechanical vs. Non-Mechanical Components

Orifice plate flow meters operate without moving parts. This makes them highly durable. They withstand harsh environments well. They handle high temperatures and pressures. They are reliable in many industrial settings.

Turbine meters use mechanical parts. These parts can degrade. Wear affects accuracy. Vibrations or solids in the fluid can damage the rotor. Although their performance is excellent under controlled conditions, reliability decreases in demanding environments.

Sensitivity to Operating Changes

Orifice plate flow meters are stable even when system conditions shift. Pressure changes or temperature variations do not significantly damage the plate. Accuracy may shift, but failure is rare.

Turbine meters are more sensitive. Sudden flow surges can overstress the rotor. Changes in fluid density influence rotational behavior. Mechanical fatigue can shorten lifespan.

Cost and Economic Considerations

Initial Investment

Orifice plate flow meters are inexpensive. The plate is simple. The installation hardware is minimal. Differential pressure transmitters add some cost, but overall, the system remains cost-effective.

Turbine meters cost more due to their precision components. Rotors, bearings, and sensing electronics require careful manufacturing. Their initial investment is higher.

Long-Term Costs

Over time, orifice plate systems retain low costs. Maintenance is minimal. Replacement plates are cheap.

Turbine systems incur ongoing expenses. Bearings and rotors may require replacement. Calibration must be scheduled. Repairs cost more. Over the long term, turbine meters may become expensive unless used in clean, stable environments.

Application Suitability Across Industries

Where Orifice Plate Flow Meters Excel

Orifice plate flow meters thrive in general industrial flow measurement. They perform well in oil and gas pipelines. They serve chemical plants with mixed fluids. They work in steam systems and high-temperature processes. Their simplicity and durability make them ideal for rugged conditions.

Where Turbine Flow Meters Excel

Turbine meters excel in applications requiring precision. They appear in fuel measurement. They serve in clean water distribution. They are used in aerospace testing and refined chemical processes. Their accuracy makes them valuable when fluid properties remain stable and contamination is minimal.

Comparing Response to Changing Conditions

Pressure, Temperature, and Flow Variability

Orifice plate flow meters respond predictably under variable conditions. They continue to measure flow even when the system is unstable. The relationship between pressure drop and flow rate remains mathematically reliable.

Turbine meters react more strongly to variations. Density changes affect rotor speed. Temperature shifts influence viscosity. Flow surges can create measurement spikes. They require stable operating conditions for best performance.

Conclusion

Orifice plate flow meters and turbine flow meters each offer unique advantages. Orifice plate flow meters provide durability, simplicity, and broad applicability across many industries. They tolerate demanding environments and variable fluid conditions. Their accuracy is sufficient for many processes, and their low cost makes them attractive for large-scale systems.

Turbine flow meters deliver higher accuracy when conditions are controlled. They provide fast response, excellent repeatability, and precise measurement for clean, stable fluids. However, they need careful maintenance, and they can suffer in harsh environments.

Choosing between the two requires understanding the fluid, the operating conditions, and the measurement goals. When reliability and simplicity are essential, orifice plates excel. When precision and fast response are required, turbine meters may be the better choice. Both play important roles in modern flow measurement, and both remain essential tools for engineers seeking accurate and efficient system operation.