Unlocking the Future: Discover the Secrets of Large 3D Printers That Will Change Everything!

In recent years, large 3D printers have emerged as a pivotal force in the realm of modern technology, reshaping how we approach manufacturing, design, and innovation. Unlike their smaller counterparts, these machines can create intricate and sizable objects, opening the door to possibilities that were once confined to imagination. The growing interest in large 3D printing spans various industries, from aerospace and automotive to healthcare and construction, making it a significant topic for anyone interested in the future of production. In this article, we will delve deep into the features, specifications, and uses of large 3D printers, providing you with insights that could inspire your next project or business venture.

Understanding Large 3D Printers

Large 3D printers, as the name suggests, are designed to produce significant-sized objects, often exceeding the build volume of standard 3D printers. While a typical 3D printer might create small prototypes or components, large 3D printers can fabricate entire parts or models, making them ideal for industries that require large-scale production. The technology behind these printers often involves advanced additive manufacturing processes, such as Fused Deposition Modeling (FDM) or Stereolithography (SLA). These machines can utilize a variety of materials, including thermoplastics, resins, and composites, allowing for a diverse range of applications. From my friend who runs a small architectural firm, I learned how they use large 3D printers to create scale models of buildings, which has dramatically improved their client presentations and project proposals.

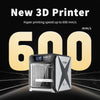

Key Features of Large 3D Printers

The features that set large 3D printers apart from standard models are crucial in determining their usability and performance. One of the most significant aspects is the build size; many of these printers can accommodate objects that are several meters in length, width, and height. Additionally, resolution plays a critical role, as higher resolution allows for more detailed prints, which is essential in fields like dentistry and jewelry design. Speed is another vital feature; large 3D printers often incorporate faster extrusion mechanisms and efficient slicing software to reduce print times. Lastly, ease of use is paramount, with many models featuring user-friendly interfaces and automated calibration systems. My friend, who is a hobbyist in 3D printing, often notes how these features have made large-scale printing accessible even to those with minimal technical knowledge.

Specifications to Consider

When exploring large 3D printers, several specifications are worth considering to ensure you choose the right machine for your needs. Print volume is perhaps the most critical specification, as it determines the maximum size of objects you can create. Layer height is another essential factor; lower layer heights typically result in smoother finishes and greater detail, but they can also increase print times. Nozzle size influences the speed and thickness of the extrusion, with larger nozzles allowing for quicker prints but sacrificing some detail. Understanding these specifications is vital for tailoring your 3D printing projects to specific applications, whether it's prototyping, artistic creations, or functional parts. A colleague of mine in the automotive industry emphasized how selecting the correct print volume and layer height significantly affected their prototype development time and accuracy.

Applications of Large 3D Printers

The versatility of large 3D printers has led to their adoption across various industries, each utilizing the technology to innovate and solve complex challenges. In aerospace, for instance, companies are leveraging large 3D printing to create lightweight yet durable components, reducing aircraft weight and improving fuel efficiency. The automotive sector benefits similarly, with manufacturers producing large parts for vehicle prototypes, resulting in quicker design iterations. In construction, large 3D printers are even being used to print entire buildings, significantly cutting down on labor costs and construction time. Healthcare is another area where large 3D printing is making waves, particularly in the production of customized prosthetics and orthopedic implants tailored to individual patients. By hearing about these applications from friends in these industries, it's clear that large 3D printers are not just a trend but a transformative technology.

Embracing the Future of Large 3D Printing

In summary, large 3D printers present an exciting frontier in the world of manufacturing and design. Their unique features, extensive specifications, and wide-ranging applications highlight their transformative potential across various industries. As technology continues to evolve, the implications for the future of production and creativity are profound. Whether you're a hobbyist, an entrepreneur, or simply curious about the capabilities of large 3D printers, embracing this technology could lead to innovative solutions and groundbreaking projects. The future of manufacturing is here, and it's time to explore what large 3D printers can do for you!