Unlock the Secrets: Discover the Ultimate Guide to Choosing the Perfect 3D Printer Filament!

When embarking on the journey into the world of 3D printing, one of the most critical decisions you'll face is selecting the right 3D printer filament. The filament you choose can significantly impact the quality, durability, and finish of your printed projects. With a plethora of filament types available, each with unique properties and applications, it can be overwhelming to determine which one is best suited for your needs. Whether you're printing intricate models or functional parts, understanding the nuances of different filaments can help you achieve the best results. By making an informed choice, you can elevate your 3D printing experience and produce stunning prints that meet your expectations.

Understanding 3D Printer Filament Types

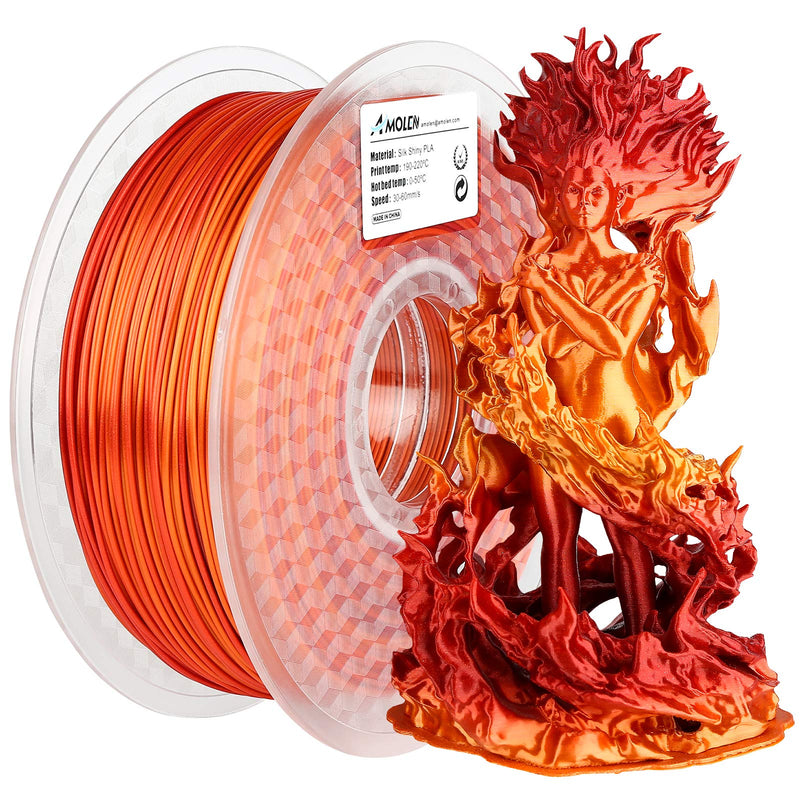

3D printer filaments come in various types, each designed for specific applications and offering distinct properties. The most popular filaments include PLA, ABS, PETG, and TPU. PLA (Polylactic Acid) is a biodegradable filament derived from natural sources like corn starch. It’s known for its ease of use, vibrant colors, and minimal warping, making it an excellent choice for beginners and general-purpose printing. ABS (Acrylonitrile Butadiene Styrene) is favored for its toughness and impact resistance, often used in functional prototypes and automotive parts, although it can be a bit more challenging to print due to its tendency to warp. PETG (Polyethylene Terephthalate Glycol) offers a balance between the ease of PLA and the durability of ABS. It boasts excellent strength and flexibility, making it suitable for items requiring durability. Lastly, TPU (Thermoplastic Polyurethane) is a flexible filament ideal for creating rubber-like objects, such as phone cases or seals. Understanding these types helps in selecting the right filament for your specific printing needs.

Common Filament Materials

Each filament material has its own set of characteristics that affect the printing process and the final product. PLA is praised for its low printing temperature and ease of use, but it can be less durable than other materials, making it unsuitable for high-stress applications. ABS is stronger and more heat resistant, but it emits fumes during printing and requires a heated bed to minimize warping. PETG combines the best of both worlds with its excellent layer adhesion and strength, but it can be prone to stringing if not dialed in correctly. TPU is unique due to its flexibility, but this can make it more difficult to print with standard setups. My friend recently tackled a project using TPU for a pair of custom shoe soles, and while the prints came out beautifully, adjusting his printer settings took some trial and error. Knowing the strengths and weaknesses of these materials can help you select the best filament for your project.

Evaluating Filament Quality

The quality of 3D printer filament can significantly affect your printing results. Several factors contribute to filament quality, starting with diameter consistency. A filament with an inconsistent diameter can lead to uneven extrusion, resulting in poor print quality. Additionally, moisture absorption is a crucial factor; many filaments, particularly PLA and Nylon, are hygroscopic, meaning they absorb moisture from the air, which can cause bubbling and poor layer adhesion during printing. Color fidelity is another consideration, especially if you require specific colors for your projects. High-quality filaments offer vibrant colors and consistent results, while lower-quality options may lead to dull prints or unexpected color variations. A friend of mine once invested in a cheaper filament, only to find that the colors were muted and the prints were riddled with imperfections. Evaluating filament quality before purchasing can save you time and frustration.

Choosing the Right Filament for Your Project

To choose the appropriate filament for your project, consider several key factors, including strength, flexibility, and finish. If your project requires robust and durable parts, ABS or PETG may be ideal due to their strength and heat resistance. For aesthetic models where detail and finish are paramount, PLA is often the go-to due to its ability to produce sharp details and vibrant colors. If flexibility is a requirement, then TPU is the best choice, especially for items that will undergo bending or stretching. Additionally, think about the environment in which the printed object will be used. For outdoor use, UV-resistant materials may be necessary. My friend recently printed a decorative outdoor sign using PETG, and he was pleased with how well it held up against the elements. When you align your filament choice with your project requirements, you can ensure a successful print.

Storage and Maintenance of Filament

Proper storage and maintenance of 3D printer filament are essential for ensuring longevity and optimal performance. Filament should be stored in a cool, dry place to prevent moisture absorption, which can lead to printing issues. Many enthusiasts use airtight containers with desiccants to keep their filaments dry. Additionally, it’s important to avoid exposing filament to extreme temperatures, as this can affect its performance when printing. Some users opt for vacuum-sealed bags to provide an extra layer of protection. Regularly checking the condition of your filament can also help; if you notice any brittleness or discoloration, it may be time to replace it. A friend of mine learned this lesson the hard way when he tried to print with a spool that had been exposed to humidity, resulting in a failed print. Keeping your filament in optimal condition will help you get the most out of your 3D printing experience.

Key Takeaways on 3D Printer Filament Selection

In conclusion, selecting the right 3D printer filament is a vital step in ensuring the success of your printing projects. By understanding the various filament types, evaluating quality, and considering project requirements, you can make informed decisions that lead to outstanding print results. Additionally, proper storage and maintenance will help prolong the life of your filament and enhance your overall printing experience. As you embark on your 3D printing journey, remember that the filament you choose can make all the difference in bringing your creative ideas to life.