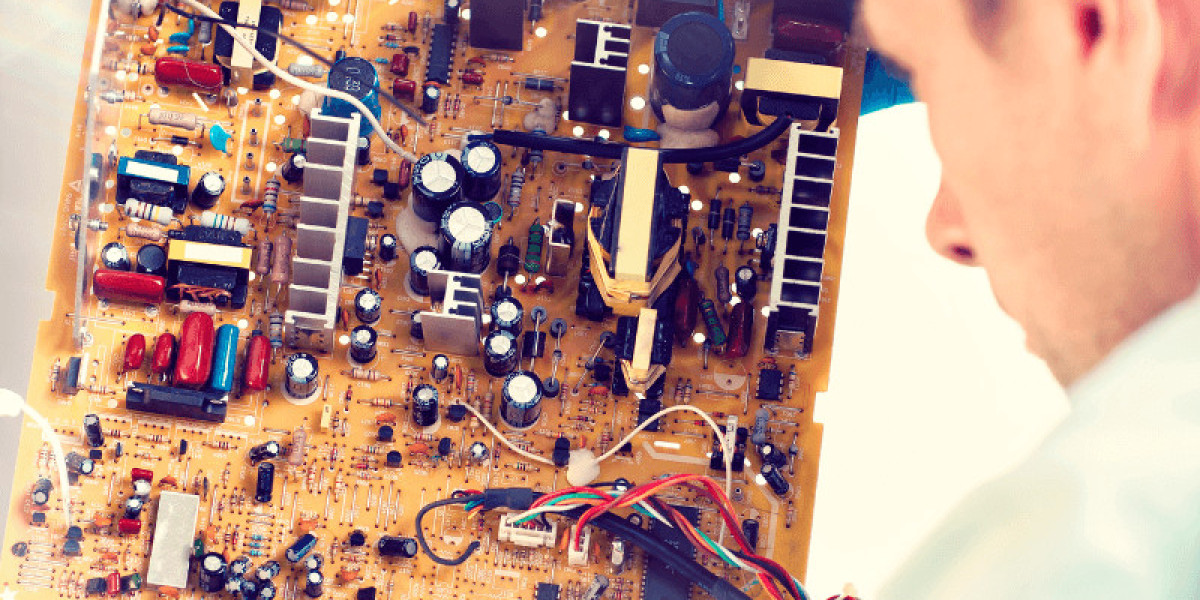

In the world of electronics, the Printed Circuit Board (PCB) is the fundamental building block that interconnects components, enabling devices to function seamlessly. The success of any electronic product heavily depends on the quality and precision of its PCB design. This is where expert PCB layout services become critical. Wagner Engineering, a trusted name in engineering consulting, offers comprehensive PCB layout services tailored to meet the exacting demands of modern electronic designs.

What Are PCB Layout Services?

PCB layout services involve creating the physical design and arrangement of electronic components on a printed circuit board. This includes placing components, routing electrical connections, managing signal integrity, ensuring thermal performance, and optimizing the board for manufacturability and cost-effectiveness.

The layout phase transforms a schematic diagram into a practical blueprint that can be fabricated and assembled, making it one of the most critical stages in electronics design. Wagner Engineering specializes in delivering PCB layouts that are precise, efficient, and manufacturable, ensuring your project’s success from prototype to production.

Why Quality PCB Layout Services Matter

A well-executed PCB layout is crucial for:

Signal Integrity: Proper trace routing and component placement reduce noise, crosstalk, and electromagnetic interference, ensuring reliable device operation.

Thermal Management: Strategic layout helps dissipate heat effectively, preventing component failure and improving device lifespan.

Manufacturability: Designing for production avoids costly errors, reduces assembly issues, and shortens time-to-market.

Cost Efficiency: Optimized layouts reduce material waste, minimize board size, and lower manufacturing costs.

Compliance: Meeting industry standards for safety and performance is easier with professional layout design.

Wagner Engineering understands these factors and integrates them into every PCB layout project.

Wagner Engineering’s PCB Layout Services: A Detailed Overview

1. Schematic Review and Analysis

Before beginning the layout, Wagner Engineering’s experts perform a detailed review of your electronic schematic. This ensures a thorough understanding of the circuit’s functionality, critical nets, and design constraints.

2. Component Placement

Strategic component placement is the foundation of a successful PCB layout. Our engineers arrange components to minimize signal path lengths, facilitate heat dissipation, and support mechanical constraints.

3. Layer Stack-Up Design

Determining the optimal number of layers and their configuration is vital for signal integrity and electromagnetic compatibility (EMC). Wagner Engineering designs layer stacks tailored to your device’s performance requirements and budget.

4. Trace Routing

Routing electrical connections is a complex task requiring precision. Our team ensures all signal, power, and ground traces are routed efficiently, considering impedance control, differential pairs, and high-speed signals where necessary.

5. Thermal and Mechanical Considerations

Effective thermal management strategies are incorporated into the layout to prevent overheating. Mechanical constraints such as board shape, mounting holes, and connector placements are carefully integrated.

6. Design Rule Checks (DRC) and Simulation

Wagner Engineering performs rigorous design rule checks and simulations to validate clearances, signal integrity, and thermal performance. This step minimizes costly revisions and production delays.

7. Manufacturing Documentation

Detailed fabrication and assembly drawings, along with Gerber files, drill files, and bill of materials (BOM), are prepared to facilitate smooth manufacturing and assembly.

Industries Served by Wagner Engineering’s PCB Layout Services

Wagner Engineering’s PCB layout expertise extends across multiple sectors, ensuring customized solutions for diverse applications:

Industrial Automation: Designing PCBs for control systems, sensors, and machinery that demand high reliability and robustness.

Medical Devices: Meeting stringent quality and safety standards through precise and compliant PCB layouts.

Automotive Electronics: Supporting safety-critical and infotainment systems with layouts optimized for harsh environments.

Consumer Electronics: Enabling compact, efficient, and cost-effective designs for smart devices and wearables.

Aerospace and Defense: Providing rugged PCB layouts that comply with strict regulatory requirements.

Why Choose Wagner Engineering for Your PCB Layout Needs?

Experienced Engineering Team

Wagner Engineering boasts a team of seasoned PCB designers and electrical engineers skilled in the latest CAD tools and layout methodologies, ensuring innovative and effective designs.

Advanced Design Tools

Utilizing industry-leading software and simulation platforms, Wagner Engineering delivers high-quality PCB layouts with reduced errors and enhanced performance.

End-to-End Support

From concept through manufacturing, Wagner Engineering supports clients with consulting, design, prototyping, and troubleshooting, making it a true partner in your project’s lifecycle.

Focus on Quality and Precision

Every layout is subjected to stringent quality controls and verification steps, ensuring your PCB functions flawlessly.

Customer-Centric Solutions

Wagner Engineering collaborates closely with clients, adapting to specific project requirements, timelines, and budgets for a tailored service experience.

The PCB Layout Process with Wagner Engineering: What to Expect

Initial Consultation: Discuss your project’s goals, requirements, and challenges.

Feasibility Analysis: Evaluate schematic and design constraints.

Component Placement & Layer Stack Design: Optimize board structure.

Trace Routing & Thermal Management: Implement efficient electrical and mechanical designs.

Verification & Review: Conduct thorough checks and simulations.

Manufacturing Preparation: Deliver fabrication-ready files and documentation.

Post-Design Support: Provide assistance during prototype testing and production.

High-quality PCB layout services are essential for developing reliable, efficient, and cost-effective electronic devices. Wagner Engineering combines deep expertise, advanced tools, and a client-focused approach to deliver PCB layouts that translate your ideas into manufacturable realities.

Partnering with Wagner Engineering means gaining a collaborative engineering ally dedicated to innovation, precision, and your project’s success. Whether you’re developing industrial controls, medical devices, or consumer electronics, their PCB layout services ensure your product stands out in quality and performance.