Wire EDM Service

Electrical discharge machining (EDM) is a manufacturing process that uses electrical sparks to form metal shapes. Because of these sparks, EDM is also known as spark machining. In this process, the desired shape is cut from the metal when a current discharge or spark occurs between the two electrodes. Where the spark occurs, the metal is cut to form the desired shape and separated from the sheet metal.

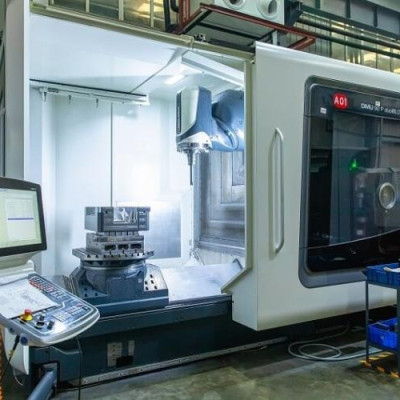

JTR as one of the most professional CNC machining parts manufacturer, we are equipped with the most advanced wire EDM machines to support our customers. Besides that, services like CNC machining, rapid prot

+6

+6